Unmatched Scalability & Efficiency

With its large yet compact surface, this machine is engineered to maximize productivity.

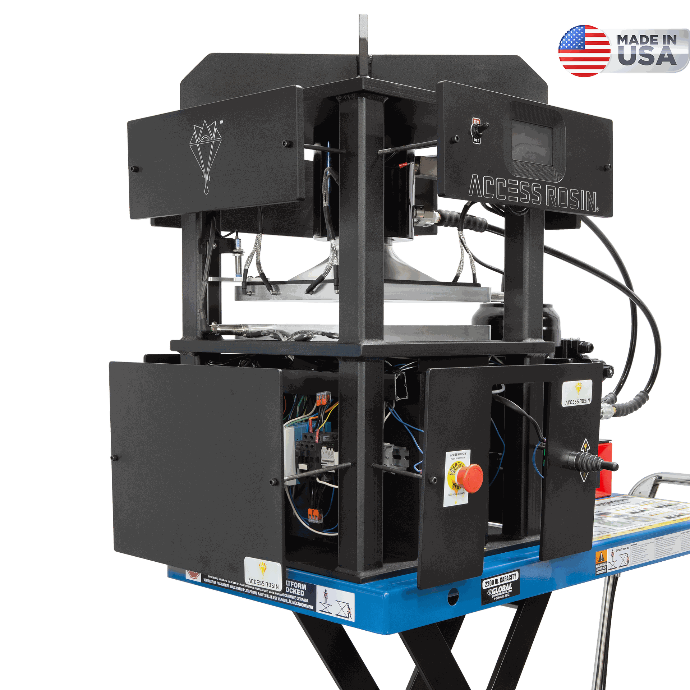

The KWÄD rosin press is a multi-bag rosin pressing machine. PRO & PRO KIT is equipped with Automated F.C.T Automation Software by Access Rosin® as the FEEL is equipped with PID controllers with fuzzy logic. The touch screen automation carries 8 total stage with a finish stage to complete a full press on the first attempt. Store up-to 20 recipe storage. Any model provides unparalleled pressure controllability ranging from 0psi-2500psi delivering adequate pounds per square inch for optimal pressing results.

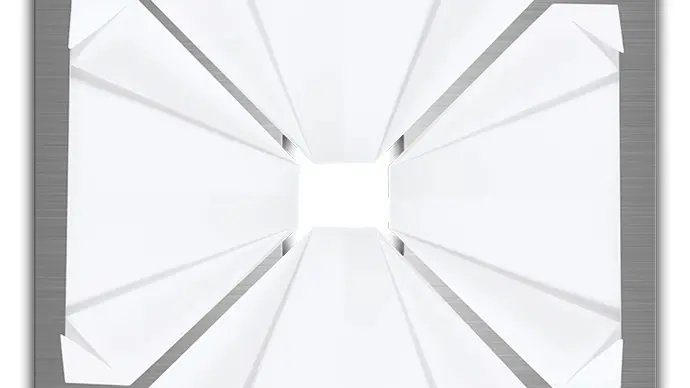

The KWÄD has a unique 12' x 12" heat plate which the shape and size creates an innovative approach to scaling rosin production. The total surface area is 135" square, enabling operators to produce rosin in bulk quantities without jeopardizing quality at scale. The collection cavity of the KWÄD measures 5.250"(w) x 17"(d) x 12" (h) and is equipped with post melt separation capability, ensuring that the rosin produced is of the highest quality. Patent No. 11,511,465

Ensure precise control over the pressure, temperature, and timing of each press recipe through automation.

Imagine the convenience of a touch screen where you can tailor pressure ranges from 0 to 2500psi and store up to 20 customized recipes.

The last thing you want is off-gassing affecting your product. KWAD's design has built-in features to prevent this, ensuring what you get is as pure as it gets.

The KWÄD has a unique 12' x 12" heat plate which the shape and size creates an innovative approach to scaling rosin production.

With its large yet compact surface, this machine is engineered to maximize productivity.

Our innovative technology minimizes collection time while preserving the rich terpenes and flavonoids. The result? A product that stands out in flavor, aroma, and potency.

Now, you could go with a competitor, but you'd be compromising on some aspect-be it scalability, quality, or safety. With KWAD, there are no compromises.

The collection cavity of the KWÄD measures 5.250"(w) x 17"(d) x 12" (h) and is equipped with post melt separation capability, ensuring the highest quality produced rosin.

Ensure precise control over the pressure, temperature, and timing of each press recipe through automation.

KWAD's patented technology isn't just about pressing rosin; it's about pressing rosin at scale without sacrificing an ounce of quality. With its large yet compact surface, this machine is engineered to maximize productivity, meaning higher returns for you.

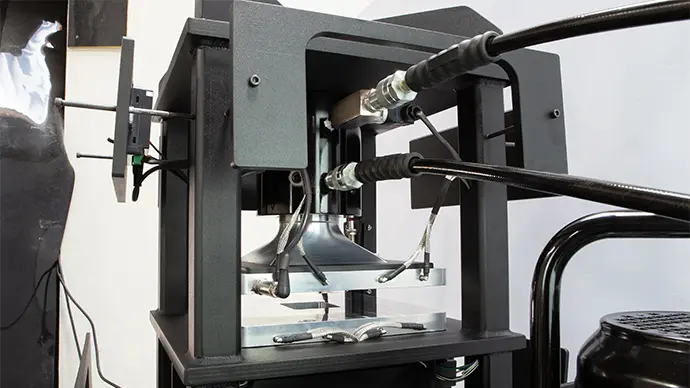

The hallmark of KWAD is its seamless integration of hydraulic controls with automation. Imagine the convenience of a touch screen where you can tailor pressure ranges from 0 to 2500psi and store up to 20 customized recipes. You're not just pressing-you're crafting.

I'm sure you've heard the phrase, 'quality over quantity.' With KWAD, it's not an either-or scenario; it's both. Our innovative technology minimizes collection time while preserving the rich terpenes and flavonoids. The result? A product that stands out in flavor, aroma, and potency.

The last thing you want is off-gassing affecting your product. KWAD's design has built-in features to prevent this, ensuring what you get is as pure as it gets.

Now, you could go with a competitor, but you'd be compromising on some aspect-be it scalability, quality, or safety. With KWAD, there are no compromises; it's the epitome of rosin extraction done right. Plus, it comes ready to use, hardwired, and mounted onto a cart.

During a press, the heat plates are temperature controlled by an intergraded PID controller within the FCT Software.

Safety measures lock the toggle switch from being able to go “down” with one hand. A two-hand activation is required before starting a cycle.

FCT Software applies, regulates, and monitors pressure as low as (0psi) and incrementally 8

PSI / 1 PPSI increments.

Press without any pressure limitations, as the KWAD can process both types of material, hash and/or flower equality as effective and efficient.