Superior Fabric Quality

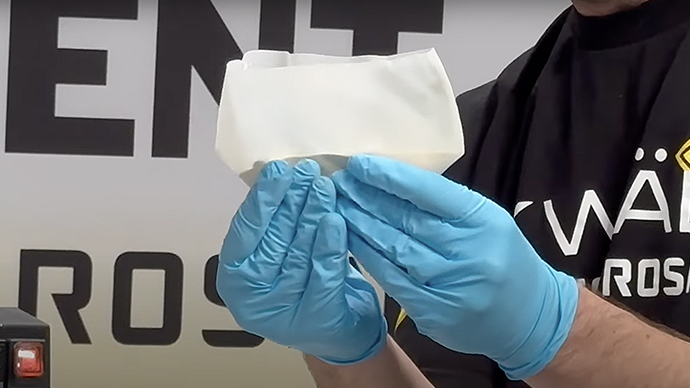

Crafted from high-quality nylon silk screen, our bags are engineered to withstand extreme pressure—up to an impressive 200,000 lbs of force—without any blowouts.

Featuring Quadruple Directional Flow technology, crafted from high-quality nylon silk screen, tested to withstand 200,000 lbs. of force with zero blowouts. Designed for optimal filtration, it ensures maximum yield and purity, making it ideal for professional extractions.

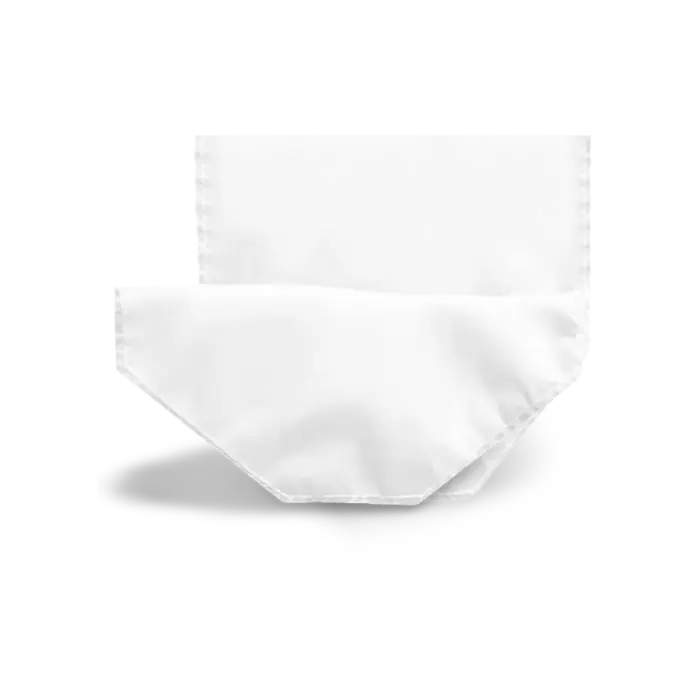

20" Square in volume, per bag

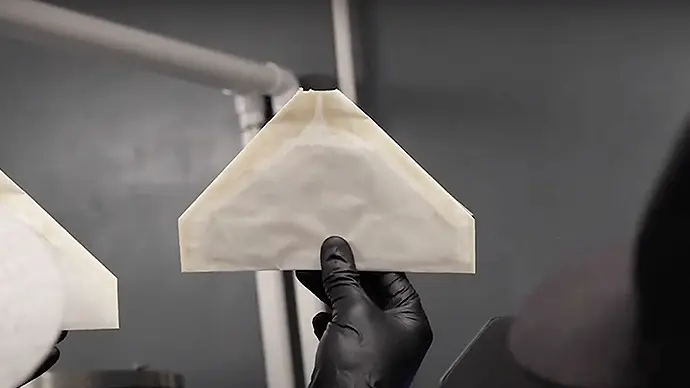

Extended Bag for easy rectangle style fold.

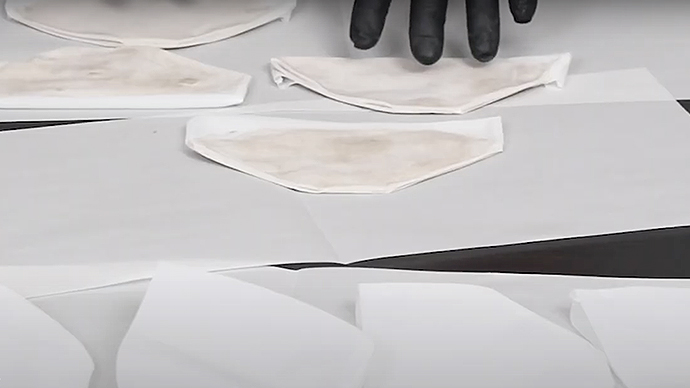

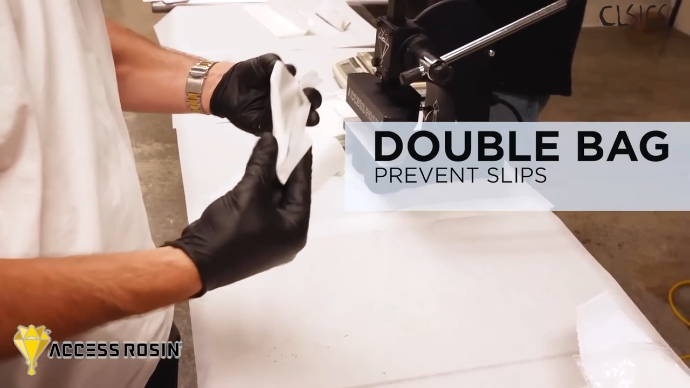

Double-bag capability

Our rosin bags are meticulously engineered with a unique trapezoid shape, precisely tailored to complement The Rosin Machine's heat plates.

Available in a range of micron sizes: 5, 25, 32, 44, 110, and 160um. Not sure which size to choose? Remember, the finer the mesh, the purer the hash.

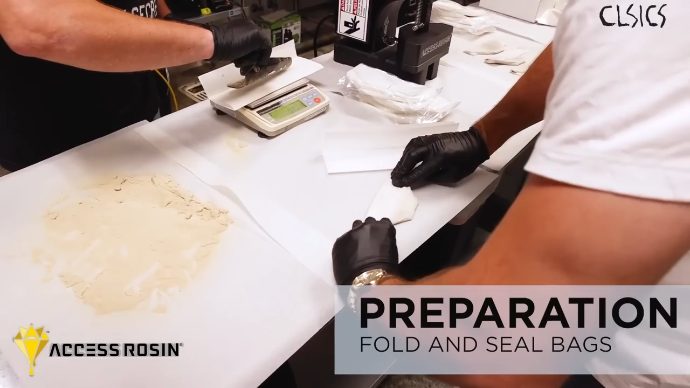

Our bags feature an extended design for easy folding in a rectangle style. This not only increases capacity by allowing for double-bagging but helps prevent slips.

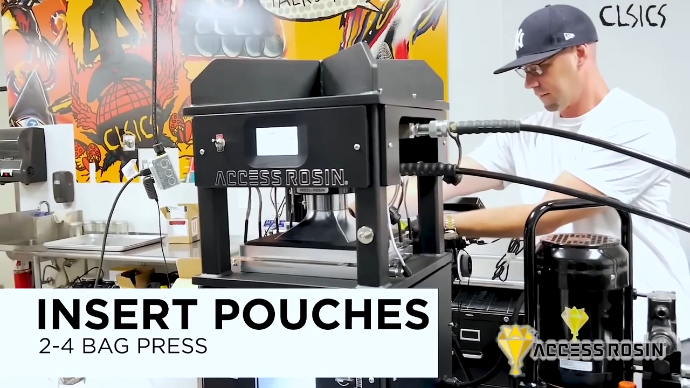

For optimal results, insert the filled bag into a pre-folded pouch. Each press can accommodate 2-4 bags, allowing for efficient processing and consistent quality in every batch.

These channels help direct the flow of resin during the pressing process, maximizing yield and efficiency.

Crafted from high-quality nylon silk screen, our bags are engineered to withstand extreme pressure—up to an impressive 200,000 lbs of force—without any blowouts.

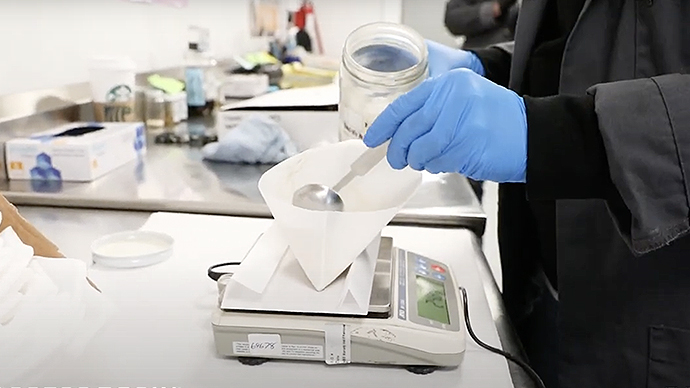

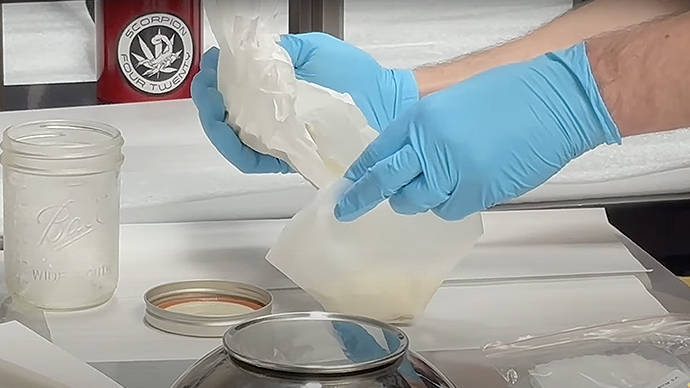

Loading your material has never been easier with our wide-mouth design, which eliminates the need for a funnel. Simply fill, fold, and seal the bag.

Our bags are engineered to prevent blowouts or slips during the extraction process. This is crucial for maintaining the integrity of your materials and ensure a clean extraction.

Minimizes the risk of contamination, allowing you to produce cleaner extracts with greater peace of mind.

Our Rosin Bags are available in a range of micron sizes: 5, 25, 32, 44, 110, and 160um. Not sure which size to choose? Remember, the finer the mesh, the purer the hash. Different strains respond better to specific micron sizes and temperatures, so selecting the right one can significantly impact your yield and quality.

Crafted from high-quality nylon silk screen, our bags are engineered to withstand extreme pressure—up to an impressive 200,000 lbs. of force—without any blowouts. This ensures that your pressing process is smooth and efficient, maintaining the integrity of your product.

Our bags feature an extended design for easy folding in a rectangle style. This design not only increases capacity by allowing for double-bagging but also helps prevent slips. Each bag offers a substantial 20" square volume, ensuring you can maximize your pressing efficiency.

Loading your material has never been easier with our wide-mouth design, which eliminates the need for a funnel. Simply fill, fold, and seal the bag. It pairs perfectly with our pre-folded parchment paper, streamlining your workflow.

For optimal results, insert the filled bag into a pre-folded pouch. Each press can accommodate 2-4 bags, allowing for efficient processing and consistent quality in every batch.

Understanding the Material-Specific Approach