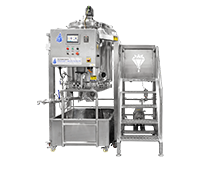

Introduction: In the competitive world of cannabis extraction, cost efficiency and operational optimization are essential for profitability. Solventless extraction methods, particularly using a Smart Agitation Water Extraction System and KWAD rosin press machine, offer a cleaner, safer alternative to solvent-based or traditional solvent-less systems and processes. This blog explores the consumables involved in solventless extraction, focusing on the cost efficiency of using Access Rosin’s KWAD technology compared to traditional presses.

Key Consumables in Solventless Extraction: Solventless extraction involves several consumables that play a crucial role in the efficiency and quality of the extraction process. Understanding these consumables and their costs is vital for optimizing operations.

- Rosin Bags:

- Usage: Rosin bags hold the cannabis material during the pressing process. They are crucial for ensuring that only the desired resin is extracted while preventing plant material from contaminating the rosin.

- Cost: Rosin bags are relatively inexpensive but are a significant consumable due to their disposable nature after a few uses.

- Parchment Paper:

- Usage: Parchment paper is used to collect the rosin as it is pressed out. It must be durable and non-stick to ensure maximum yield and easy collection.

- Cost: Parchment paper costs vary based on quality, but it is a recurring expense that adds up over large production runs.

- Wash Bags:

- Usage: Used during the initial wash process in ice water extraction to separate trichomes from plant material.

- Durability: Less frequently replaced than rosin bags, but they can rip under heavy load or sharp objects, making them an occasional consumable.

- Other Consumables:

- Gloves, Hair Nets, and Jars: Essential for maintaining hygiene and quality during the extraction process.

- Freeze Dryer Trays and Lids: While not frequently replaced, these can become consumables over time due to wear and tear.

Production Specs and Calculations: The following production capacities are based on the Smart Agitation Water Extraction System 50 Gallon, which can process substantial material over a 20-day working month.

- WPFF Input: 3000 lbs wet plant fresh frozen (WPFF) / 600 lbs if dried

- Total Mass: 1.362 million grams

- Wet Hash Production: 340,000 grams

- Dried Hash Production: 54,500 grams at 4% yield or 68,100 grams at 5% yield of total mass

- Rosin Production: 41,000 grams at 75% yield (resin to rosin) or 51,000 grams at 75% yield (resin to rosin)

- Operational Period: 20 days per month, 8 hours per day

- Wash Cycle: 38 lbs per cycle, 4 cycles per day

Comparison of KWAD Technology vs. Traditional Presses:

| Metric | KWAD Machine vs | Traditional Presses |

|---|---|---|

| Number of Presses | 1 | 6 |

| Grams / Press | 240 | 40 |

| Grams / Bag | 60 | 20 |

| Bag Size | 20” sq. | 12” sq. |

| Press Count | 227 | 227 |

| Rosin Bag / Press | 8 | 4 |

| Parchment Paper / Press | 4 | 2 |

| Rosin Bag Cost / Bag | $1.00 | $1.00 |

| Parchment Paper Cost / Pouch | $1.49 | $0.65 |

| Rosin Bag Cost / Batch | $1,816.00 | $5,448.00 |

| Parchment Paper Cost / Batch | $1,352.92 | $295.10 |

| Total Bags / Batch | 1,816 | 5,448 |

| Total Cost / Batch | $3,168.92 | $5,743.10 |

| Cost per Gram Produced | $0.06 | $0.63 |

| Cost Saving / Batch | $2,574.18 | - |

Economic Benefits of KWAD Technology: The KWAD Rosin Machine demonstrates significant cost savings compared to traditional presses. Here’s why:

- Higher Efficiency:

- The KWAD machine processes larger quantities per press, reducing the number of presses required and thereby decreasing the usage of consumables.

- Lower Consumable Usage:

- Despite higher initial costs, KWAD technology uses fewer rosin bags and parchment paper per gram of rosin produced. This results in substantial cost savings over time.

- Cost Per Gram:

- The cost per gram of rosin produced is significantly lower with the KWAD machine, making it a more cost-effective solution for large-scale operations.

Forecasting and Planning for Consumables: To maintain uninterrupted production and optimize costs, it is essential to forecast and plan for consumables. Operators should maintain a stock of consumables sufficient for at least a month’s production to avoid any disruptions.

Conclusion: Switching to Access Rosin’s KWAD technology offers significant cost advantages and efficiency improvements over traditional pressing methods. By reducing the usage of key consumables and lowering the cost per gram of rosin produced, businesses can enhance their profitability and operational sustainability. For those in the cannabis extraction industry, adopting innovative technologies like those from Access Rosin is a strategic move towards achieving long-term success.

For more detailed information and to explore Access Rosin’s range of advanced extraction equipment, visit Access Rosin’s website.

Smart Agitator

Smart Agitator Sieve System

Sieve System Iceless Pro Kit

Iceless Pro Kit Rosin Presses

Rosin Presses Pumps

Pumps Accessories

Accessories

Parchment Paper

Parchment Paper