Introduction: The cannabis industry is in a constant state of evolution, with new technologies emerging to meet the growing demands for efficiency, scalability, and quality. Access Rosin's patented Flow Control technology, protected under patent No. 11,511,465, is at the forefront of this revolution. This groundbreaking technology not only perfects the solution for scaling solventless manufacturing practices but also ensures the production of top-tier quality products that connoisseurs demand. In this blog, we will explore how Flow Control technology is transforming rosin production, making it a vital investment for facilities aiming to compete in the expanding market.

Understanding Flow Control Technology: Flow Control technology is a proprietary innovation developed by Access Rosin, designed to optimize the collection and quality of rosin during the extraction process. Here’s how it works and why it’s a game-changer:

- Precise Flow Management:

- Uniform Distribution: Flow Control technology ensures that the resin flows evenly into the collection cavity, reducing the risk of uneven pressure and temperature distribution.

- Minimized Waste: By directing the resin flow precisely, it minimizes the need for scraping and handling, thereby reducing product loss and maintaining the integrity of the rosin.

- Consistency and Quality:

- Top-Tier Products: Connoisseurs require consistent quality in rosin products. Flow Control technology delivers this by ensuring that each batch meets the highest standards of purity and potency.

- Scalability: This technology allows for seamless scaling of operations without compromising on quality, making it possible to meet increasing market demands efficiently.

Preserving Terpenes and Flavonoids: Flow Control technology also plays a crucial role in preserving the delicate terpenes and flavonoids, which are essential for the full-spectrum experience of cannabis products.

- Post-Melt Separation:

- Less Oxidation and Off-Gassing: The rosin falls off the heat plates directly into collection jars without the "waterfall" effect, reducing the time exposed to heat and air. This minimizes oxidation and off-gassing of volatile compounds.

- Higher Terpene and Flavonoid Retention: The controlled flow and immediate collection into jars preserve more of the low-temp volatile terpenes and flavonoids, enhancing the product's aroma, flavor, and therapeutic benefits.

- THC-A and Diamonds Formation:

- Enhanced Quality: By preserving more solvents (volatile terpenes and flavonoids), the rosin retains a higher potential for forming THC-A diamonds. These diamonds signify high purity and potency, appealing to discerning consumers.

- Color Spectrum Analysis:

- Executive Decision-Making: The technology allows operators to analyze the full spectrum of resin as it melts and separates, enabling better control over the quality and characteristics of the final product. This separation by color spectrum is unique and provides insights into the different fractions of rosin, helping to refine and optimize the extraction process.

The Economic Benefits of Flow Control Technology: Investing in Access Rosin’s Flow Control technology offers significant economic advantages:

- Lower Cost Per Gram:

- Efficiency Gains: By optimizing the flow of resin, this technology reduces labor costs and increases the yield per batch, significantly lowering the cost per gram of rosin produced.

- Minimal Labor Requirements: Automation and precision reduce the need for manual labor, minimizing the risk of human error and associated costs.

- Increased Throughput:

- Higher Production Capacity: With Flow Control technology, facilities can process larger quantities of cannabis material more quickly, increasing overall production capacity and profitability.

- Reduced Downtime: The streamlined process reduces downtime between batches, allowing for more continuous operation and higher output.

Convincing the Investor: Why Flow Control Technology is a Smart Investment: Investors looking to capitalize on the burgeoning cannabis market need to understand the value of investing in advanced, scalable technologies like Flow Control. Here’s why:

- Market Competitiveness:

- Staying Ahead: In a competitive market, having the most advanced technology ensures that your facility can produce high-quality products consistently, keeping you ahead of competitors.

- Brand Reputation: Consistent quality builds brand reputation, attracting loyal customers and expanding market share.

- Long-Term Sustainability:

- Future-Proofing: Flow Control technology is designed with scalability in mind, making it adaptable to future market growth and technological advancements.

- Investment in Quality: High-quality equipment reduces maintenance costs and increases operational longevity, ensuring a better return on investment over time.

Case Study: Real-World Application and Benefits Consider a production facility integrating Flow Control technology to process 55 kilos of hash rosin over 20 days with 8-hour operations daily. Here’s a breakdown of the benefits observed:

| Metric | Flow Control Technology | Traditional Methods |

|---|---|---|

| Production Capacity | Significantly Increased | Limited |

| Labor Costs | Substantially Reduced | High |

| Yield Consistency | High | Variable |

| Product Waste | Minimal | High |

| Cost Per Gram | Lower | Higher |

Conclusion: Access Rosin’s patented Flow Control technology represents a significant advancement in the solventless extraction industry. By addressing the key challenges of efficiency, consistency, and scalability, this technology provides a robust solution for facilities looking to optimize their operations and maximize profitability. Investing in Flow Control technology is not just a step forward for your production capabilities; it’s a strategic move towards securing a competitive edge in the ever-growing cannabis market.

For more detailed information and to explore Access Rosin’s range of advanced extraction equipment, visit Access Rosin’s website.

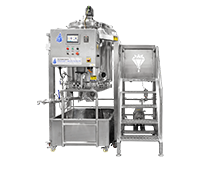

Smart Agitator

Smart Agitator Sieve System

Sieve System Iceless Pro Kit

Iceless Pro Kit Rosin Presses

Rosin Presses Pumps

Pumps Accessories

Accessories

Parchment Paper

Parchment Paper